Department of Applied Mechanics

Applied Mechanics Department is the department which is functioning in conjunction with Civil Engineering department. The subjects like Applied Mechanics, Strength of Materials, Mechanics of Structures, Geo Technical Engineering, Concrete Technology, Theory of Structures, Design of Structures etc are taught by this department for Civil engineering students. For Mechanical and Production Engineering students also the subjects Applied Mechanics and Strength of Materials are taught by this department. In this way the department is associated with other departments of the institute.

In the department there are three laboratories which are well equipped with all necessary equipment required for practical’s, project works as well as for testing and consultancy works. The major machineries available in the department includes Electronic Universal Testing Machine of capacity 1000 kN, Electronic Universal Testing Machine of capacity 400 kN, Compression Testing Machine of capacity 2000 kN, Los Angeles Abrasion testing machine, Tile Flexure testing machine, Tile Abrasion testing machine, sieve shakers, Hardness Testing machine for metals, Impact Testing machine, Direct Shear test apparatus, Plate Load Test Apparatus, CBR apparatus, rebound hammer and Ultrasonic Pulse Velocity apparatus. As these equipment are used for testing also the servicing and calibration is carried out every year for major machines.

Along with academic work, the department is also involved in testing and consultancy work. As nearly all the equipment’s are available, the testing facilities for testing of nearly all construction materials including concrete mix design is available in the department. The scrutiny work of Structural designs is also undertaken by the department. The staff of the department also undertakes field testing. Through testing and consultancy work the department is helping the Government by generating the internal revenue. Every year approximately 15 to 20 lakhs of revenue is generated by the department. In the financial year 2021-2022 the internal revenue generated by the department is approximately Rs. 21 lakhs.

The department is trying to procure some more advanced equipment’s required for advanced practical’s for students, projects of the students ,testing and consultancy work.

Program Outcomes (POs)

PO1) Basic and Discipline specific knowledge: Apply knowledge of basic mathematics, science, engineering fundamentals and discipline specific knowledge to solve core Metallurgical engineering related problems.

PO2) Problem analysis: Identify and analyse well-defined Metallurgical engineering problems using codified standard methods.

PO3) Design/ development of solutions: Design and develop solutions for well-defined technical problems and assist with the design of systems components or processes to meet specified needs.

PO4) Engineering Tools, Experimentation and Testing: Apply modern engineering tools and appropriate technique to conduct standard tests and measurements related to Metallurgical engineering.

Program Specific Outcomes (PSOs)

PSO1) Be able to apply Metallurgical concepts in the field of Extraction, Foundry, Metal Working, Physical Metallurgy and Welding.

PSO2) Be able to conduct various Destructive and Non Destructive tests

PSO3) Be able to analyze defects in Heat Treatments, Casting and Welding

PSO4) Posses the skills to communicate in both oral and written forms and work in a team.

Program Educational Objectives (PEOs)

PEO1) Our Engineers will apply Metallurgical principles in their profession.

PEO2) Our Engineers can work independently and as a leader to execute projects.

PEO3) Our Engineers will advance in their careers and continue their professional development.

Guest Lecture

1.Material Characterization

2.Heat Treatment Furnaces

3.Welding Career In Advanced Manufacturing And Industry 4.0

4.Opportunities In Metallurgy

Industrial Visits

1.Fronius India Pvt. Ltd., Bhosari, Pune

2.Metallurgy & Materials Science Dept., College Of Engineering, Pune

3.TATA Motors Foundry, Chinchwad, Pune

4.NDT Laboratory, Bhosari, Pune.

Faculty Information

|

Sr No. |

Name |

Designation |

Experience |

|

01 |

Shri. V.R. Gaikwad |

Lecturer in Applied Mechanics |

31 |

|

02 |

Shri. A.R. Bais |

Lecturer in Applied Mechanics |

18 |

|

03 |

Shri A.B. Mane |

Lecturer in Applied Mechanics |

04 |

|

04 |

Shri B.B. Kamandar |

Lab Assistant |

28 |

|

05 |

Shri. S.B. Dhindale |

Peon |

33 |

Infrastructure

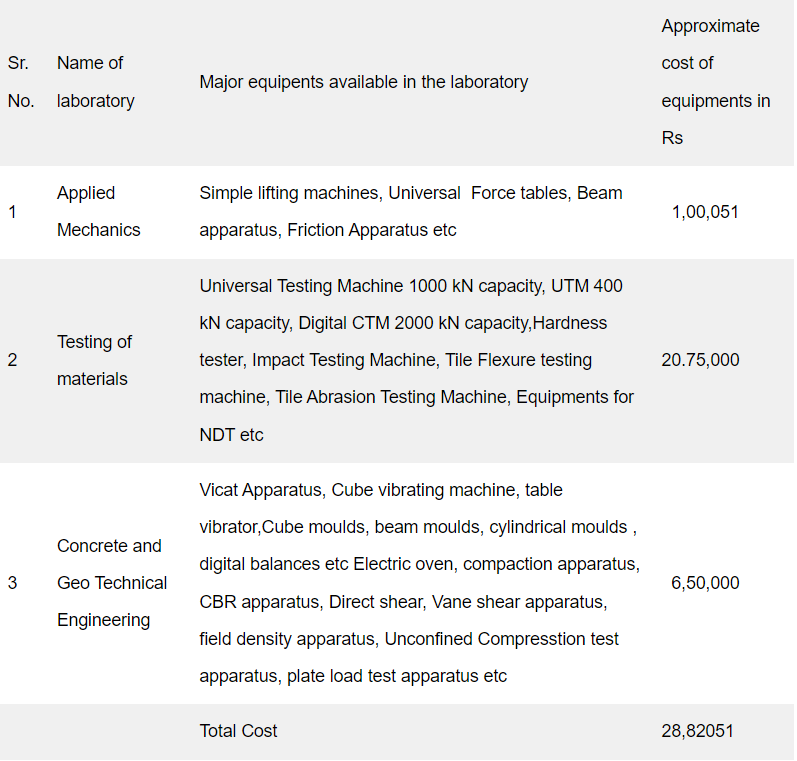

In this department three laboratories are available. The information about name of laboratory, major equipments available and approximate cost of equipment is given in the following table.

शासकीय तंत्रनिकेतन,अहमदनगर

शासकीय तंत्रनिकेतन,अहमदनगर